|

Andrew's Tips: Identifying Quality Bagpipes

By Andrew T. Lenz, Jr., Santa Cruz, California, ©2007-2008

In terms of bagpipes, it can be difficult for the untrained eye to separate the "sheep from the goats" as the saying goes. Some physical shortcomings are easy for even the newest bagpiper to spot, others are more tricky. Rather than pointing out what to look for in a good bagpipe, we're going to point out some of the things that can go wrong—be it an untrained or careless lathe operator ("turner"), an overworked or overtired shop manager, a bottom-line driven owner, over-reliance on a computer-operated machine, sloppy inspection . . . whatever.

We're going to discuss visuals below. Acoustics are more subjective and can only be tested by playing the instrument. A library of books will never replace the ear of an experienced piper when evaluating the sound of a set of pipes.

All the problem bagpipes below come from over half a dozen different Scottish, North American, and European makers that are well known—none are from Pakistan or other countries known to regularly turn out bagpipes of very questionable quality.

Things to watch out for in a set of bagpipes

|

| The wood of this drone has been cut just short of the mount to make the defect obvious—the bore and the exterior of the wood are far from concentric. |

|

| This drone shipped out from a maker with no tenon or hemp stop for the tuning pin. |

|

| These are from the same set. Makers are usually better about sorting their wood so they are similar in color. Also notice the shape difference. |

|

| Aside from the color difference, there are several problems with this set. Notice the distance of the twin lines from the drone cord channel and also the line from the shoulder. Also notice the combing next to the shoulder on the bottom from the top, the bottom has more lines. There are additional combing inconsistencies as well. |

|

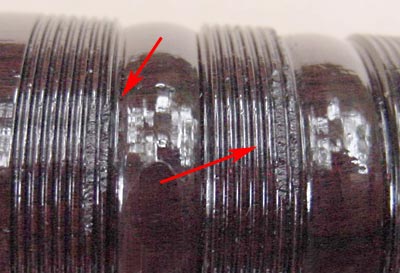

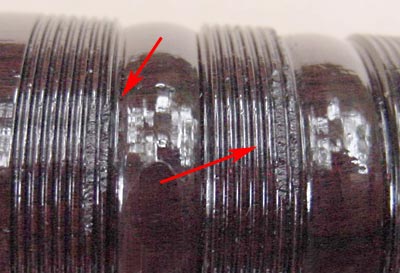

| Here you can see where the wood has shredded during turning on the lathe. This effect is called "torn combing." |

|

| Aside from the torn combing on this drone, the combing stops abruptly at the shoulder. Very odd. |

|

| The first series of combing on the left has seven teeth, the next has six. Also, we see a "terraced effect." The profile should appear smooth, like a slope, not stepped. |

|

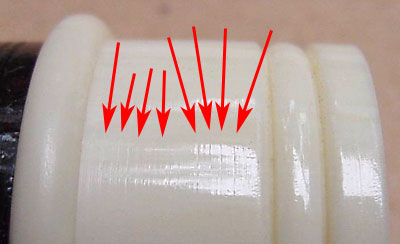

At the top we see inconsistencies in the combing. The top comb is about a third of the width of the rest. Toward the bottom we also see a similar problem, the last ones are larger or smaller than the center combs.

Also noticeable is the crack running the length of the drone. While cracks and splits can happen to even the best made pipes, they should be repaired or replaced.

And we also see that the mount has completely fallen off. Loose mounts are a problem that may result if the wood is not properly dried (seasoned) prior to turning. Green wood is very prone to shrinking which can cause oval bores, loose mounts and overly-tight fits—not to be confused to swelling due to moisture as seen in blowpipes. On the other hand, subjecting a set of pipes to extreme conditions can also result in mounts falling off!

|

|

| Another example of the mounts falling off. Also in this case the turner removed too much wood for the mounts so it was built back up with filler then turned again to the proper size! Yipe! (You can see the yellow hemping used to try to keep two of the loose mounts in place.) |

|

Another sign of likely inadequate wood seasoning, the ring cap popped off. Threaded mounts may not guarantee prevention of the mounts loosening, but it certainly will help and also keep them from coming completely off as easily. |

|

Here we see that the ferrule was never faced with the wood. They should be flush, but you can see a distinct step.

Also, from a design standpoint, the thickness of the ferrule is disproportionately large to the thickness of the wood. It's possible that the turner removed too much wood then compensated with an overly thick ferrule.

|

|

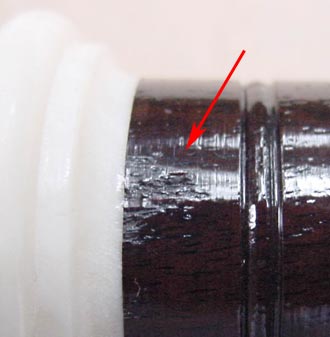

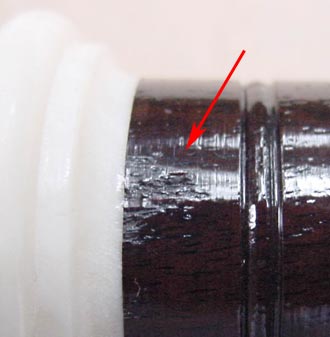

| Here when shaping the mount, the tool was either too dull or held at the wrong angle and therefore the blade skipped resulting in "chattering." |

|

Here you can see a flaw resulting from either a natural defect in the wood or from poor workmanship. This would be rejected by a high quality shop.

What is good in this photo is the joint between the wood and the mount, it is very even and there is no step or gap between them.

|

|

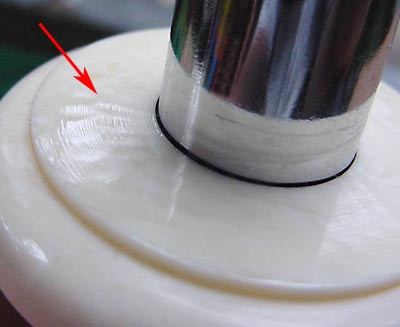

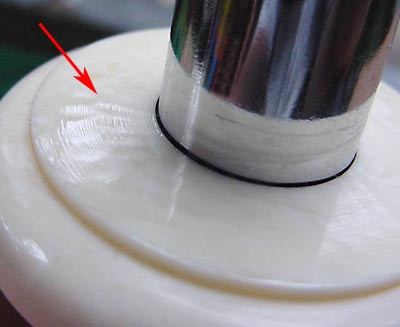

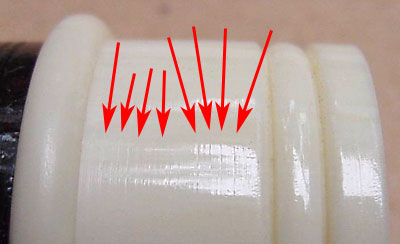

| This synthetic ivory ferrule should be smooth. We can see "turning lines" from the shaping—another undesireable characteristic. |

|

| Another example of turning lines. Not as dramatic, but nonetheless, undesirable. |

|

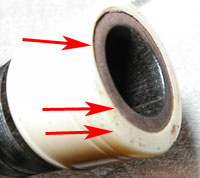

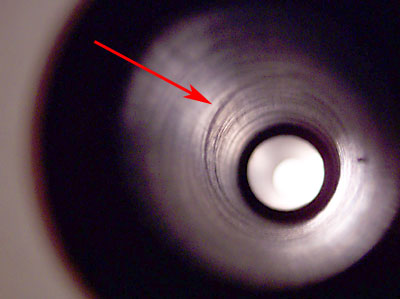

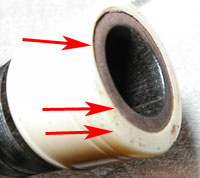

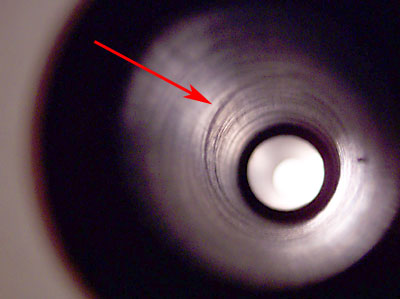

| This bass drone tuning chamber isn't hairy and doesn't have loose bits, which is good, but inadvertent threading marks were created during the boring process—such grooves are undesirable. (There are some who argue that anything less than a glass-smooth bore is the shoddy work, others will argue a bit of a texture tests with better drone harmonics.) More important though, is that the bore walls are parallel, which these are. |

|

| Here we see a substantial pit in the wood. Flaws are going to happen in natural wood products, but you'd hope to never see one like this in a set sold as a top quality instrument. |

|

This bass drone top was delivered with an obvious flaw that is completely unacceptable. This should have been caught both in the pipe maker's shop as well as by the retailer and should have never made it into a piper's hands.

|

|

Not to be neglected, chanters can also fall victim to problems. Here we see the wood chipped out on the top side of the fingering holes. This is usually indicative of bits that need sharpening or an impatient drill operator.

Also, while it's harder to notice, the top hole is out of alignment with the lower two holes since it's shifted to the left. Since this chanter was not marketed as having some revolutionary "ergonomic finger hole placement" we'll call it as it appears to be, an error.

|

Hopefully, you've gained some insight into a properly made bagpipe. You may also be interested in reading my article Appraising Bagpipes.

If you have comments or suggestions about this page, please contact me.

This page last updated Sunday, March 14, 2010.

Page first created in February 18, 2007.

|

|